When planning a new logistics building – and for retrofits too – green building and sustainability factors gain in importance. SSI SCHÄFER offers several green solutions. Moreover, the company offers further services from energy consulting and planning, certification and monitoring, and subsidy consulting. Johannes Zimmermann, Director Construction Management at SSI SCHÄFER, provides deeper insights in the following interview.

In order to maintain the competitiveness of a logistics company in the long run, it is important to create a sustainable intralogistics and building infrastructure. Especially with regard to a pending CO2 tax, all divisions of a company should aim at considerably reducing CO2 emissions. Among useful measures are the elaboration of new mobility concepts (e.g. use of load trains, drones or low-emission vehicles), limitation to short transport routes on the company premises and the integration of regional suppliers for purchasing. Furthermore, an intelligent, low-emission conveying system and the use of alternative energy sources (e.g. PV system to supply the vehicle fleet with green electricity) for decentralized energy supply on site can help to reduce CO2 emissions.

Companies have to reduce their CO2 emissions to be able to pay less CO2 tax. For this purpose, several options are available: An ecologically sensitive building technology, a comprehensive energy concept with storage and regulation options, use of green electricity, green gas etc., waste heat utilization apply to building and energy supply.

Furthermore, innovative conveying systems and storage-retrieval machines with intelligent control, predictive maintenance and efficient use of storage density contribute to the reduction of CO2 emissions. Maximum storage consolidation may increase the storage capacity by 90% and reduce the space requirements by 40%. As a consequence, building volume, building and possible cooling costs. Further useful measures are a future-oriented mobility concept including loading and supply infrastructure on the company premises, compensation measures (such as roof greening, planting of trees in outdoor areas and similar), external projects and an optimization of external and internal processes for CO2 compensation.

A holistic approach is crucial: Not only the building including energy supply, but also outdoor areas and employees should be in focus. The building can be improved by additional measures, such as the use of energy-efficient illumination systems, controls, pumps or the installation of systems for self-generated electricity such as CHP or PV systems. The production systems can be equipped with state-of-the-art and energy-efficient technology (e.g. pumps, drives, regulation valves). Furthermore, rain and gray water can be used depending on application purpose and water treatment. The company premises can be optimized by creating green areas or installing electrical loading stations in the parking lots. It is particularly important to raise awareness of the employees how to implement sustainability in everyday working life and how the company can benefit from it. For instance, the user behavior can be optimized with trainings or the creation of sustainability guidelines or an ecological policy. In case of new acquisitions, the use of a sustainable acquisition guideline is recommended.

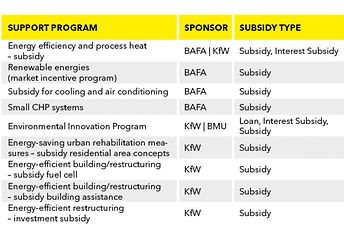

Subsidies have to be researched separately for each project. Each state has its own subsidy programs and corresponding guidelines. The table below shows a summary of the available subsidies throughout Germany offering financial aid.