The 3 key principles for effective consulting when implementing a WMS

In the world of intralogistics, where efficiency and precision are crucial, the Warehouse Management System (WMS) plays a central role in success. WMS systems are the backbone of any modern warehouse, enabling companies to optimize their stock levels, accelerate process orders, and seamlessly integrate the entire logistics process. But how can companies ensure they are getting the best possible WMS solution that meets their individual needs? The answer lies in complete logistics and software consulting from a single source.

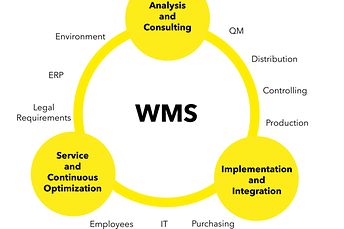

The implementation of a WMS is a complex matter that takes various aspects of logistics and information technology into account. Holistic logistics and software consulting helps to ensure that companies receive the best possible WMS solution. The maxims of consulting should be followed - learning from the past, considering trends and future plans, and continuously adapting to ensure long-term success in the market. At SSI SCHAEFER, these are the software experts from the WAMAS Enterprise team, who focus specifically on the core element WMS from the WAMAS portfolio.

By relying on both logistics and software consulting from a single source from SSI SCHAEFER, companies can benefit from a variety of synergy effects. The clearly defined goal is to ensure an optimal overall solution from conception to implementation and productive use.

Complete analysis and consulting

Customers receive a comprehensive analysis of their current intralogistics processes based on their corporate and, in particular, their defined logistics strategy. Working together with the software consultants from WAMAS Enterprise makes it possible to identify weak points and develop customized solutions that are precisely tailored to individual requirements.

Effective implementation and smooth integration

By working with a team of consultants who understand both the logistical requirements and the technical aspects, it is possible to ensure that the WAMAS implementation goes smoothly and that the WMS is optimally tailored to the specific warehouse requirements. Once, the integration into the overall IT and logistics concept is complete, SSI SCHAEFER's customer service team ensures that warehouse operations can be guaranteed at all times.

Service and continuous optimization

SSI SCHAEFER's customer service is always available for ongoing operations. This ensures that warehouse operations can be guaranteed at all times. As intralogistics is subject to constant change, companies must be able to adapt and continuously optimize. In today's world, efficient warehouse management is a must to remain competitive. If required, WAMAS Enterprise can provide professional advice throughout the entire life cycle of the warehouse management system. This ensures that the WMS is continually adapted and optimized to meet new requirements.

Conclusion

A warehouse management system is an indispensable tool for companies that want to optimize their warehouse management and improve their logistics processes. By providing complete logistics and software consulting from a one-stop source, WAMAS Enterprise customers can be sure to receive the best possible WMS solution that meets their individual requirements throughout the entire lifecycle. Regardless of the industry, the future of intralogistics lies in customized, complete solutions as well as continuous adaptation and further development.

About the author

Gerd Sulzbacher, Team Leader for Logistics Consulting at SSI SCHAEFER, is an industrial engineer by training. After graduating, he gained experience in production and transport logistics. Since 2011 he works at the SSI SCHAEFER location in Friesach and has supported WMS projects in various industries (food, retail, 3PL, fashion) as Lead Logistics Consultant. His team supports several national and international companies with the implementation of WAMAS Enterprise WMS and assists customers in the continuous development and improvement of their intralogistics processes.