SSI SCHAEFER Group achieves sales growth and a clearly positive result in the 2024 financial year

Group revenues of EUR 2.0 billion almost 5% higher than in the previous year

Incoming orders rose significantly by 18.7% to EUR 2.0 billion

Main driver was the largest business unit, Logistics Solutions, which saw an increase in order volume and revenues

Customer Services continues strong performance

Subdued demand and competitive pressure are affecting the Products & Equipment and Plastics business units

Neunkirchen/Siegerland (Germany), April 7, 2025 – The SSI SCHAEFER Group, a family-owned company with a history of over 85 years and a leading international solution provider for all areas of intralogistics, recorded a 4.8% increase in sales to EUR 2.0 billion in the 2024 financial year, based on preliminary figures. This growth was mainly driven by a significant increase in sales of 14.8% in the Logistics Solutions division and the consistently positive performance of the Customer Services division. The positive development in the largest division, Logistics Solutions, was due, among other things, to a well-selected portfolio mix that enabled the division to serve different market needs and thereby successfully complete customer projects. In addition, the largest order intake for an individual project in the history of SSI SCHAEFER had a positive impact on the order intake at group level, which, at EUR 2.0 billion, was 18.7% higher than in the previous year. By contrast, the difficult market environment and weak demand, particularly from the automotive sector, were noticeable in the Products & Equipment and Plastics divisions. Overall, the SSI SCHAEFER Group reports a significantly positive group result on a preliminary basis.

Successful completion of the milestone project with Coop and consistent implementation of sustainability goals

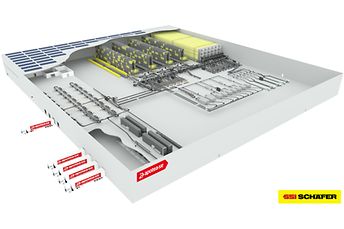

A significant milestone in the 2024 financial year was the completion of the fully automated SSI Case Picking system for Coop, a leading food retailer in Sweden. A key requirement for this was the successful cross-location collaboration between the Logistics Solutions and Customer Services divisions and with the core suppliers. The project marks the Group's largest logistics solution to date, in which 95% of all picking processes are automated.

Strategically, the Group continued to focus on strengthening its innovative capabilities last year with the aim of playing a key role in shaping the digital and sustainable transformation of the intralogistics industry. One example of this is the development of the FastBots Solution, which is based on a fleet of high-performance robots that flexibly operate between the warehouse and workstations. It was presented for the first time at the international trade fair for intralogistics and process management, LogiMAT, in Stuttgart in March 2025. In addition, the implementation of the sustainability strategy was consistently continued and the SSI SCHAEFER Group's responsibility towards the environment and society was documented in its third sustainability report.

„Despite the persistently challenging market environment and a reluctance to invest, the SSI SCHAEFER Group has made significant progress in all key performance indicators and has largely achieved the targets set for the 2024 financial year. Now we want to use the tailwind and push ahead with our initiatives focusing on customer value, growth, innovations, and project governance to continue our course of sustainable profitability. The SSI SCHAEFER Group has successfully continued on its chosen path and – true to our central target of customer satisfaction – has made great strides. In the current financial year, we will continue to focus on not only being a reliable partner for our customers, but also on meeting their needs as best as possible, far beyond their immediate requirements.“

SSI SCHAEFER has implemented a sustainable and highly automated distribution centre for Coop in Eskilstuna, Sweden. 95% of the picking processes in the highly automated facility are automated.

The FastBots solution is based on a fleet of high-performance robots that flexibly operate between the warehouse and workstations.